|

shaanxi dinol environmental protection technology co.,Ltd.

|

Sodium Hypochlorite disinfection equipment

| Price: | 9899.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

generation of sodium hypochlorite can be accomplished using electrolyzer systems, crystallized salt is dissolved and used for electrolysis On-site.

Generation of sodium hypochlorite can be accomplished using electrolyzer systems. In these systems, crystallized salt is dissolved and used for electrolysis On-site.The electrolysis cells are designed for low brine feed flow rates, narrow electrode gaps, and produce sodium hypochlorite concentrations approaching one percent.

This systems are generally configured with the following components:

1) electrolysis cells which is the Core components of the systems.Electrolyzes the 2-5% brine solution to produce sodium hypochlorite disinfection solution.

2) Salt dissolver : Provides the required salt solution for electrolysis.

3) PLC Control System: Directly monitor the safe and reliable operation of the entire generator system and the status of self-detection, alarm and self-stop in case of malfunction.

4) power supply:DC power rectifier,Using professionally produced constant voltage and constant current power supply,Electric conversion efficiency> 92%,Low calorific value and stable operation,Electrolysis efficiency reaches 89-90%, saving energy consumption.

5) Storage tanks:One-piece molding without welding seam.

6) Dosing pumps with dosing controls: Provides the needed disinfection dose based upon the chlorine residual or flow rate of a receiving stream.

The main technical parameters:

TYPE | DN-E100 | DN-E300 | DN-E500 | DN-E1000 | DN-E2000 |

available chlorine (g/h) | 100g/h | 300g/h | 500g/h | 1000g/h | 2000g/h |

DC/V | DC/V≤5V

| 20V/DC | ≤30V/DC | 7L/h----8L/h

| ≤40V/DC |

DC/A | DC/A≤125A±20%

| 85A/DC

| ≤120A/DC

| 20L/h----25L/h

| ≤160A/DC |

Flow (L/h) | 20L/h----25L/h | 30L/h--35L/h | 75L/h--85L/h | 30L/h----35L/h

| 105L/h--110L/h |

Brine concentration/sea water | 2-5% | 2-5% | 2-5% | 2-5% | 2-5% |

Capacitance pressure | ≤0.2MPa | ≤0.2MPa | ≤0.2MPa | ≤0.2MPa | ≤0.2MPa |

Other specifications | According to customer needs | According to customer needs | According to customer needs | According to customer needs | According to customer needs |

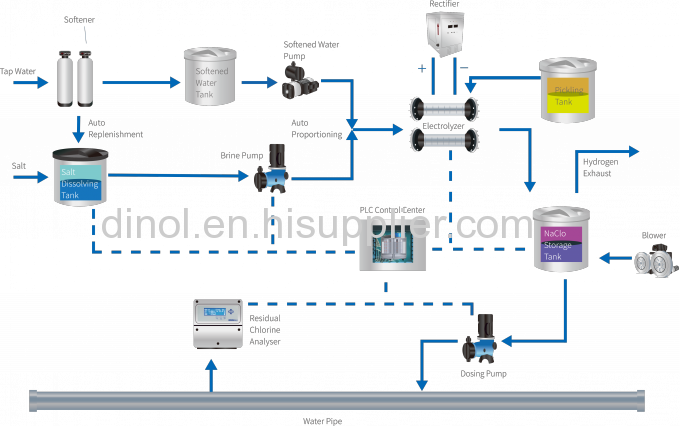

System Flow:

① Influent water passes through a water softener to reduce hardness therefore reducing the scaling of electrodes and lengthening the cleaning time

② Salt is dissolved by softened water into saturated brine in the tank.

③ The saturated brine will be diluted into 2.5%-3%, then pass through the electrolytic cell and finally be electrolyzed into 0.8-1% solution of sodium hypochlorite.

④ The 0.8-1% hypochlorite solution flows into a storage tank. Hydrogen that is the only byproduct of the process, is safely vented to the atmosphere.

⑤ The residual chlorine detector will monitor residual chlorine and return feedback to the PLC center. According to preset standards, the PLC Center will adjust the speed of the dosing pump.

On-site Sodium Hypochlorite Generators are the advanced chlorination systems available producing a sodium hypochlorite based mixed oxidant solution in a safe, economical and reliable way, suitable for various occasions where sodium hypochlorite is required for disinfection:

1) water treatment:disinfection of drinking water including rural drinking water and urban water supply;

2) Sewage treatment of Hospital ;

3) Disinfect tableware and utensils in restaurants and canteens;

4) Disinfection of tableware, vegetables, fruits, etc. at home;

5) Disinfection of Swimming pool water;

6) Cooling circulating water treatment of Power plant:Used for disinfection and algae elimination;

7) Industrial waste water treatment:Degraded COD,BOD,Ammonia nitrogen concentration,It has a high removal rate of organic matter and chroma;

8) Other occasions requiring of disinfection.